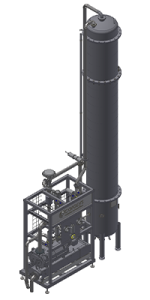

Exhaust gas scrubber

The exhaust gas scrubber system VS is used for cleaning undesirable loads from exhaust gas, e.g. solvents, or for the targeted production of solutions by absorption of gas components such as aqueous ammonium solution.

Advantages and functions

- Scrubber system for chemisorption and physisorption of exhaust gas loads, optionally with washing medium recycling

Feasibility studies and concept selection, including optional test module for operation at the customer - Specific boundary conditions (TA-Luft, ATEX, FDA, DGRL, …)

- Batch operation and continuous operation

- Options

- Jet scrubber or blower for suction

- Circulation of scrubbing medium with / without cooling

- Selection of scrubbing media

- Recycling of scrubbing media

- Process-specific materials

- Manual operation up to automation

- Modular and mobile system

Technical description

The waste gas is fed into the scrubber column C01 and flows upwards through the specifically selected components of the column. At the same time, scrubbing liquid is introduced at the top of the column and flows downwards through the column and its internals in countercurrent to the waste gas. This results in intensive contact between the scrubbing medium and the exhaust gas and thus in the removal of the pollutants from the exhaust gas with simultaneous loading of the scrubbing medium. The selection and dimensioning of the internals is essential here, which depends, among other things, on the exhaust gas constituents and quantities, the operating conditions such as vacuum/temperature or the liquid or gas phase that determines the transfer of substances. The now cleaned waste gas flows out of the head of the column, while the loaded scrubbing medium is collected in the sump of the column, recirculated or pumped out of the column sump.

The waste gas is fed into the scrubber column C01 and flows upwards through the specifically selected components of the column. At the same time, scrubbing liquid is introduced at the top of the column and flows downwards through the column and its internals in countercurrent to the waste gas. This results in intensive contact between the scrubbing medium and the exhaust gas and thus in the removal of the pollutants from the exhaust gas with simultaneous loading of the scrubbing medium. The selection and dimensioning of the internals is essential here, which depends, among other things, on the exhaust gas constituents and quantities, the operating conditions such as vacuum/temperature or the liquid or gas phase that determines the transfer of substances. The now cleaned waste gas flows out of the head of the column, while the loaded scrubbing medium is collected in the sump of the column, recirculated or pumped out of the column sump.

The use of special high-boiling detergents such as polyglycols is particularly effective for washing low-boiling solvents. Internal recycling according to the VSR system is recommended for these detergents. The loaded washing agent is heated via E01 and E02 and fed into a separate stripping column C02, where it flows into the sump of the column with simultaneous stripping with steam, which takes up the loading of the washing medium, and is cleaned and cooled via E01 and E03 and pumped back to washing column C01. The loaded steam is condensed at the top of the column with a defined reflux ratio.

Technical specification

| Exhaust gas | < 10 to 10.000 Nm3/h |

| Scrubbing medium | Water, aqueous solutions, specific glycols |

| Operating pressure | From vacuum to overpressure |

| Heating medium | process specific |

| Cooling medium | process specific |