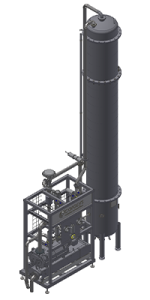

Exhaust gas vapours low temperature condensation

The low-temperature condensation system VCC is used to remove unwanted loads from exhaust gas, e.g. solvent, by cooling and thus very extensive condensation of the solvent.

Advantages and functions

- Low temperature condensation of exhaust gas loads through targeted cooling of the exhaust gas flow

- Often multi-stage condensation, especially to avoid ice formation and to use different operating pressures

- Feasibility studies and concept selection, including optional test module for operation at the customer

- Specific boundary conditions (TA-Luft, ATEX, FDA, DGRL, …)

- Batch operation and continuous operation

- Options

- Self-priming blasting nozzle or vacuum pump system

- Fractionated multi-stage condensation

- Process-specific materials

- Manual operation up to Automation

- Modular and mobile system

- Straightforward operation, low maintenance, long service life

- Fully automatic operation with SPS control and touch panel as standard equipment

- Optional integration of the water deaeration in process control system and remote maintenance

- Individual construction and dimensioning adapted to local conditions

- Use of components and models specified by customers

- Water deaeration as a compact, frame-mounted unit

Technical desription

The exhaust gas is fed into the partial condenser E01 and flows downwards in this condenser with the condensing exhaust gas charges, which leads to a defined depletion of the exhaust gas contents. Waste gas and liquid flow together into the temperature-controlled sump V01, where the cleaned waste gas is separated from the liquid and, depending on the process requirements, either discharged or fed via a vacuum pump or a blower (e.g. VP01) into a second process stage consisting of condenser E02 and collection vessel V02 at a lower temperature. For many batch processes, it is sufficient to treat the loaded liquid after the process; for larger loading quantities, continuous depletion or pumping off of loaded solvent is required.

The exhaust gas is fed into the partial condenser E01 and flows downwards in this condenser with the condensing exhaust gas charges, which leads to a defined depletion of the exhaust gas contents. Waste gas and liquid flow together into the temperature-controlled sump V01, where the cleaned waste gas is separated from the liquid and, depending on the process requirements, either discharged or fed via a vacuum pump or a blower (e.g. VP01) into a second process stage consisting of condenser E02 and collection vessel V02 at a lower temperature. For many batch processes, it is sufficient to treat the loaded liquid after the process; for larger loading quantities, continuous depletion or pumping off of loaded solvent is required.

For the recovery of partial fractions, e.g. aromas in beverage production or partial components to be recovered from waste gas, a temperature graded condensation can be applied.

Technical specification

| Exhaust gas | < 10 to 1.000 Nm3/h |

| Vapors | < 10 to 5.000 kg/h |

| Operating pressure | From vacuum to overpressure |

| Heating medium | Process specific |

| Cooling medium | Process specific |