Water thermal sanitization

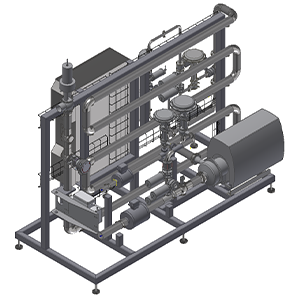

The thermal water treatment, system MWT, is used for the conditioning of already desalinated water to produce water or steam in the quality WFI, pure steam and ultrapure steam.

Advantages and functions

Technical description

Desalinated water is filtered and, using corosys technology, is fed via a vacuum degassing column into a buffer tank for the water. The pre-cleaned and already degassed water, which exceeds the hygiene requirements for the water, is pumped over with the P01 pump and heated – depending on the requirements for hot or cold water – with E01 and brought completely to hygiene requirements with reverse osmosis modules, continuously monitored with a conductivity measurement in the return flow of the MWT system.

Desalinated water is filtered and, using corosys technology, is fed via a vacuum degassing column into a buffer tank for the water. The pre-cleaned and already degassed water, which exceeds the hygiene requirements for the water, is pumped over with the P01 pump and heated – depending on the requirements for hot or cold water – with E01 and brought completely to hygiene requirements with reverse osmosis modules, continuously monitored with a conductivity measurement in the return flow of the MWT system.

From the circuit, the purified water can either be led to storage tanks for intermediate storage or directly to the evaporator systems for the production of WFI or pure steam or ultrapure steam. Both the withdrawn quantities and the circulation quantities are measured currently and cumulatively.

Within the unit, the efficiency of supplied water is optimised within safe hygienic limits by minimising losses via the degassing unit and recirculating the aqueous partial flow.

Technical specification

| Water | < 10 to 1.000 m3/h |

| Conductivity | <10 µS/cm for condensate (Pharmacopoeia compliant) |

| Heating medium | Process specific |

| Cooling medium | Process specific |